What makes A 1000 Series Shredder different?

A high torque shredder that has no “catastrophic cost” parts. They have been designed out of this shredder making it the least expensive cost per ton HIGH TORQUE SHREDDER to operate.

- NO COMPLEX EXPENSIVE GEARBOX to wait for and replace from the manufacturer but a simple double HD chain drive and oil bath system. Easy access panels to help with inspection.

- A redundant and inexpensive “off the shelf” hydraulic system employing dual motors that are not only inexpensive and American Made but are also readily available.

- Every part of the cutting head can be replaced inexpensively making rebuild cost lower and more predictable from knives to spacers to super nuts to dead zones.

- A proprietary 6 key shaft design to eliminate shaft “washout”. The old hex shaft others use has been eliminated along with all of its well known service problems.

- Downtime and catastrophic costs are shredder owner’s number 1 industry complaint. All 1000 series machines both portable and stationary have a MODULAR HEAD that can be swapped out at far less cost than any other manufacturer for a 1 hour change out to make downtime near zero. An extra head is offered at a very inexpensive price to help owner have near ZERO DOWNTIME.

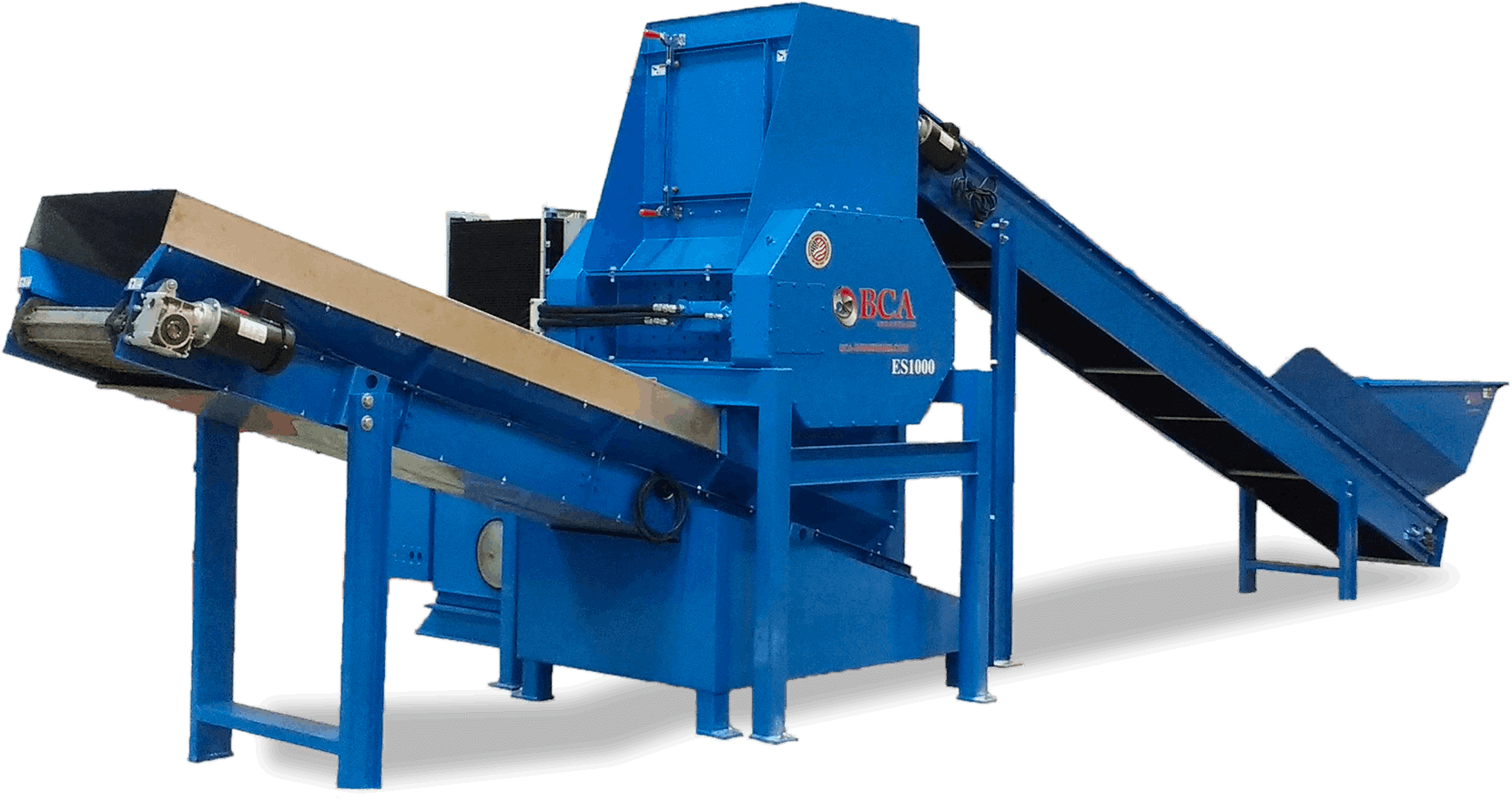

- All 1000 series system shredders, conveyors, magnets etc. are built by BCA here in Milwaukee. Fully integrated to work together for maximum efficiency with one number to call if there’s any issue.

- Elimination of a full time millwright or mechanic for an owner. A 1000 series head rebuild program where an owner can inexpensively have the knives and head rebuilt by the factory with a service warranty.

THE BCA Head Service Program

- The 1000 series head was uniquely engineered in the design to be lighter weight and still industrial durable. This allows BCA to offer the ONLY TRUE PORTABLE shredder in its class.

- The 1000 series head removes with a standard 5,000 lb. forklift. 4 bolts and 6 hoses and it gets placed on our CUSTOM STEEL PALLET INCLUDED to protect it while shipping.

- The head can be shipped back to BCA in usually 2 days from anywhere in the US using inexpensive LTL carriers.

- The head is factory serviced by experienced technicians with new or rebuilt BCA knives and spacers. This is done at a labor and materials cost (including rebuilt knives) of just $7,900.00 if there are no other parts needed. FACTORY CERTIFIED AND SHIPPED BACK usually with a 7 to 10 day turnaround. On a primary tire shredder for instance that is less than 6 cents per tire.

- Knowing that you do not require that level of skill on staff allows the shredder owner to greatly REDUCE LABOR COST and uncertainty.