Industrial Shredders Shred the Competition

Our machines shred

Tires | Batteries | Plastic | & More

Tires | Batteries | Plastic | & More

BCA offers unmatched industrial shredders, recycling equipment, and system components. We manufacture stationary and portable shredders for tires, plastic, electronic waste, and more. Our shredders are fast, effective, and minimize wasted material. As a family-owned company since 1998, we’re proud to say all our machinery is built in-house.

Stationary systems built for your business, building, and your budget.

Shredder and recycling equipment that can travel with you.

Add or replace components on your existing machinery.

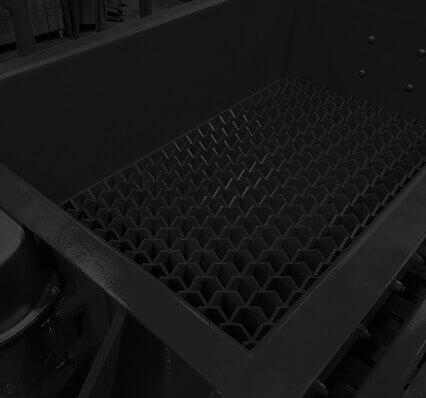

BCA’s Triplus shred system precisely and accurately shreds material, allowing for screenless sizing in a single pass. With power efficiency as much as 150% more than standard shredders, our Triplus system can save you thousands of dollars in energy and labor every month.

LithiBatt, a division of BCA industries, is now providing complete lithium-ion (Li-ion) and lithium-iron phosphate (LiFePO4) battery recycling systems in collaboration with leading global partners. Read more about these battery recycling systems.

BCA serves a wide variety of industries all over the world. We produce effective and durable shredders for recycling, factory waste, construction debris, industrial applications, and more. Our shredders have you covered when it comes to:

Our customer service department provides fast and friendly support for all of our customers. Whether you’re looking to lease a shredder, need maintenance done on your machinery, or are looking for parts, our customer service team can help.

We rebuild worn-out shredders to get them working like new

We produce all parts in-house and repair your machine if anything goes wrong

Regular inspections ensure your machine lasts longer and works better

Get your equipment now and pay later with our comfortable financing options

Have an idea? BCA’s experienced machinists have developed several industry-changing products from start to finish. Whether you're still working out the details of your idea, or have fully designed CAD drawings, we can help make your product a reality.