Industrial Copper Shredder Machines for Sale

Copper shredder machines for sale from BCA Industries process wire, scrap and other copper materials with industrial-grade power. We build stationary and mobile copper wire shredders for manufacturers, recyclers and electrical equipment producers nationwide. Each shredder boosts copper recovery, reduces waste volume and improves processing speed. Request a quote today to find the right copper shredder machine for your operation.

Copper Shredders For Sale

Browse our copper shredder machines for sale, including options built for wire, scrap and mixed copper materials. BCA Industries offers portable, mobile and stationary copper shredders designed for demanding industrial recycling applications.

Types of Industrial Copper Shredders We Sell

BCA Industries manufactures copper shredder machines for every stage of the recycling process. Whether you need a high-capacity copper wire shredder for large-scale operations or a mobile unit for job site flexibility, we offer durable solutions tailored to your workflow. Our copper shredding machines handle copper cable, tubing, sheets and mixed scrap with consistent performance and minimal maintenance.

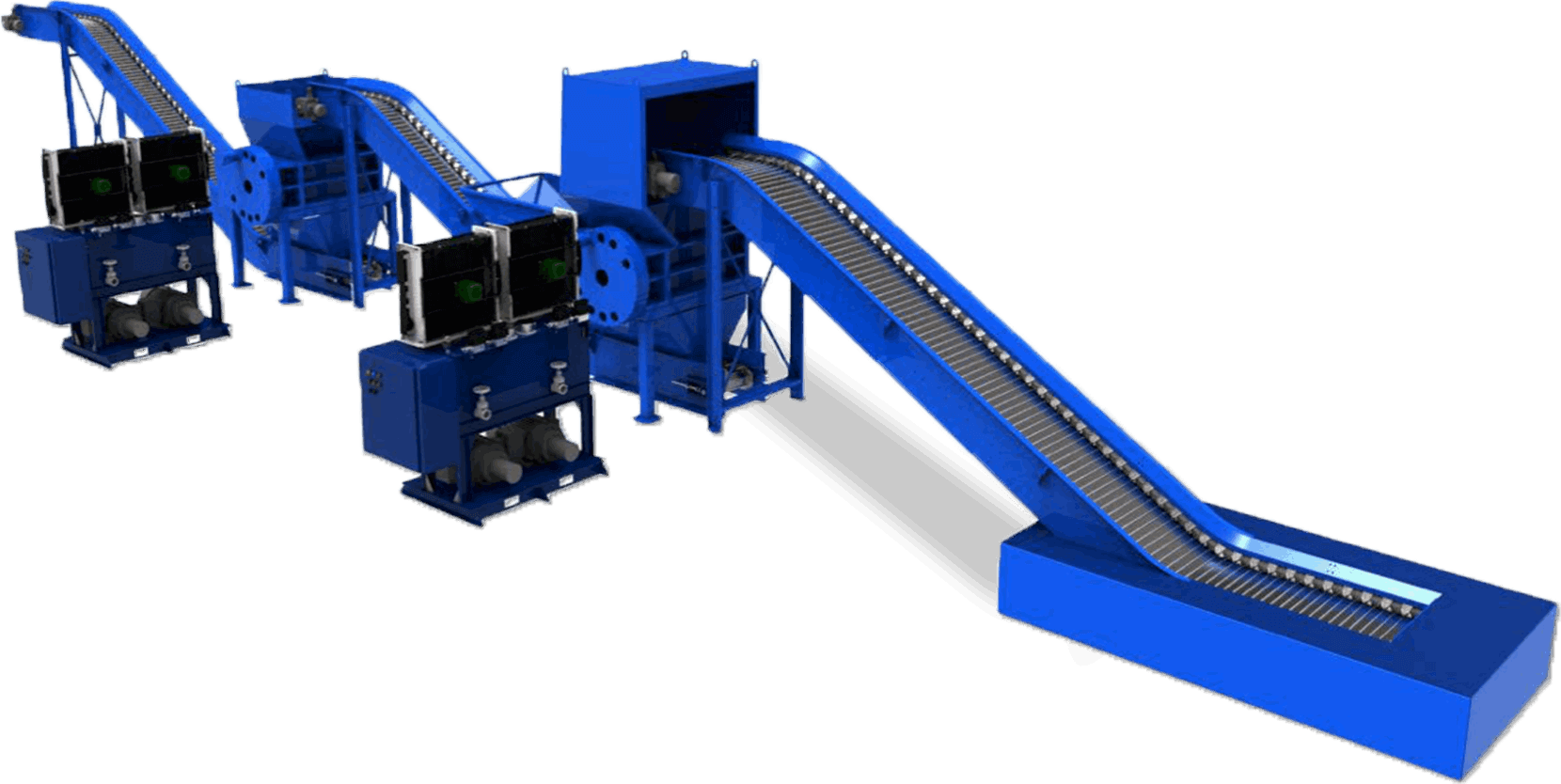

Stationary Copper Shredders

Stationary copper shredders from BCA Industries are built for high-volume processing of wire, tubing and heavy scrap. Each copper shredder machine delivers continuous throughput and rugged performance for manufacturing and recycling centers. Our shredding machines handle tough copper materials with speed and consistency, making them ideal for fixed-site operations demanding scale and reliability.

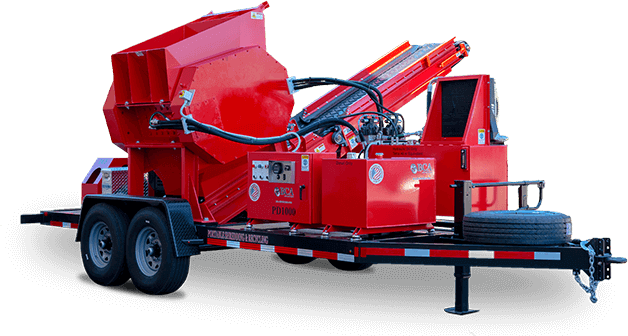

Portable Copper Shredders

Our portable copper shredders give you on-site flexibility without sacrificing power. Designed for construction, electrical and remote recycling work, each mobile copper shredder machine processes wire, cable and mixed copper scrap where it’s generated. Easy to move and quick to set up, portable shredding machines help reduce transport costs and keep your recycling process efficient from any location.

Patented Triplus® Knife System

The patented Triplus® Knife System is available on all BCA copper shredders. This three-stage cutting system—shred, chip and size—produces 85% correctly sized copper material on the first pass without the need for sizing screens. Whether you’re processing copper wire, tubing or mixed scrap, the Triplus® Knife System reduces energy use by up to 150% compared to standard shredders while increasing output and consistency.

How We Build Your Copper Recycling Shredder

Every copper shredder machine we build starts with a detailed consultation. We review your facility layout, copper material types and recycling goals to engineer a solution matched to your operation. Our team uses advanced CAD software to model your copper shredder system, factoring in material flow, loading methods and output needs.

Once approved, your copper shredding machine is manufactured in-house using precision machining and quality components. Before shipment, we test every copper wire and scrap shredder under load conditions to confirm reliability and performance.

We also provide:

- Shredder Installation

- Operator Training

- 7-Day Support on All Systems

Our copper shredders are built for consistent, reliable performance from day one.

How Copper is Processed After Shredding

Shredding is the first step in efficient copper recovery. Once copper wire, tubing or scrap is reduced to manageable pieces, it moves through downstream systems for sorting, separation and refinement. A typical copper recycling process includes:

- Magnetic separation to remove ferrous contaminants from shredded material

- Granulation to reduce copper into fine, uniform particles

- Air separation to strip away insulation and light contaminants

- Screening and collection to isolate clean copper for resale or refining

This post-shred process improves purity, increases resale value and prepares copper for direct use in manufacturing or smelting applications.

What Can a Copper Shredder Machine Process?

Copper shredder machines from BCA Industries are built to handle a wide range of copper-rich materials found in scrap, demolition and recycling environments. Our copper shredders deliver consistent results across:

- Copper wire and cable harnesses

- Insulated wiring with mixed plastics

- Copper tubing and plumbing scrap

- Flat copper sheets, plates and stamping cutoffs

- Electric motor windings and small e-waste components

Whether you’re processing loose wire or bulky industrial scrap, our shredders simplify copper recovery and help maximize material value.

Copper Shredder Machine Support

Maximize the life and performance of your copper shredder machine with full-service support from BCA Industries. Our team helps reduce downtime and protect your investment with fast access to parts, scheduled inspections and expert rebuilds.

We offer:

- Regular shredder inspections to catch wear early and keep your copper wire and scrap shredder running efficiently.

- Quick access to replacement parts for critical components minimizes disruptions to your copper recycling process.

- Shredder head rebuilding to restore worn cutting systems and extend equipment life.

Whether you’re processing copper cable, tubing or mixed scrap, we keep your machines working like new.

Copper Shredder Leasing & Financing

Copper shredder machines for sale don’t have to strain your budget. BCA Industries offers leasing and financing options to help you access high-performance equipment with manageable monthly payments. Whether you’re expanding your recycling operation or entering the copper recovery market, we’ll help you get the right copper shredder machine in place without large upfront costs. Talk to our team today about financing options for copper wire shredders, scrap shredders and complete processing systems.

Contact our experts today for a quote on shredding machines for copper and other industries.